Happy Tuesday! Today was fairly steady. A tad chilly out but it was still a good day.

I started my day on the southside of Edmonton. I had a few appointments in the south before heading to the west end. And then I finished my day on the north side.

My first customer today got a rock chip on his way to work early this morning. He said he heard a loud bang but because it was still dark out, he couldn’t see anything.

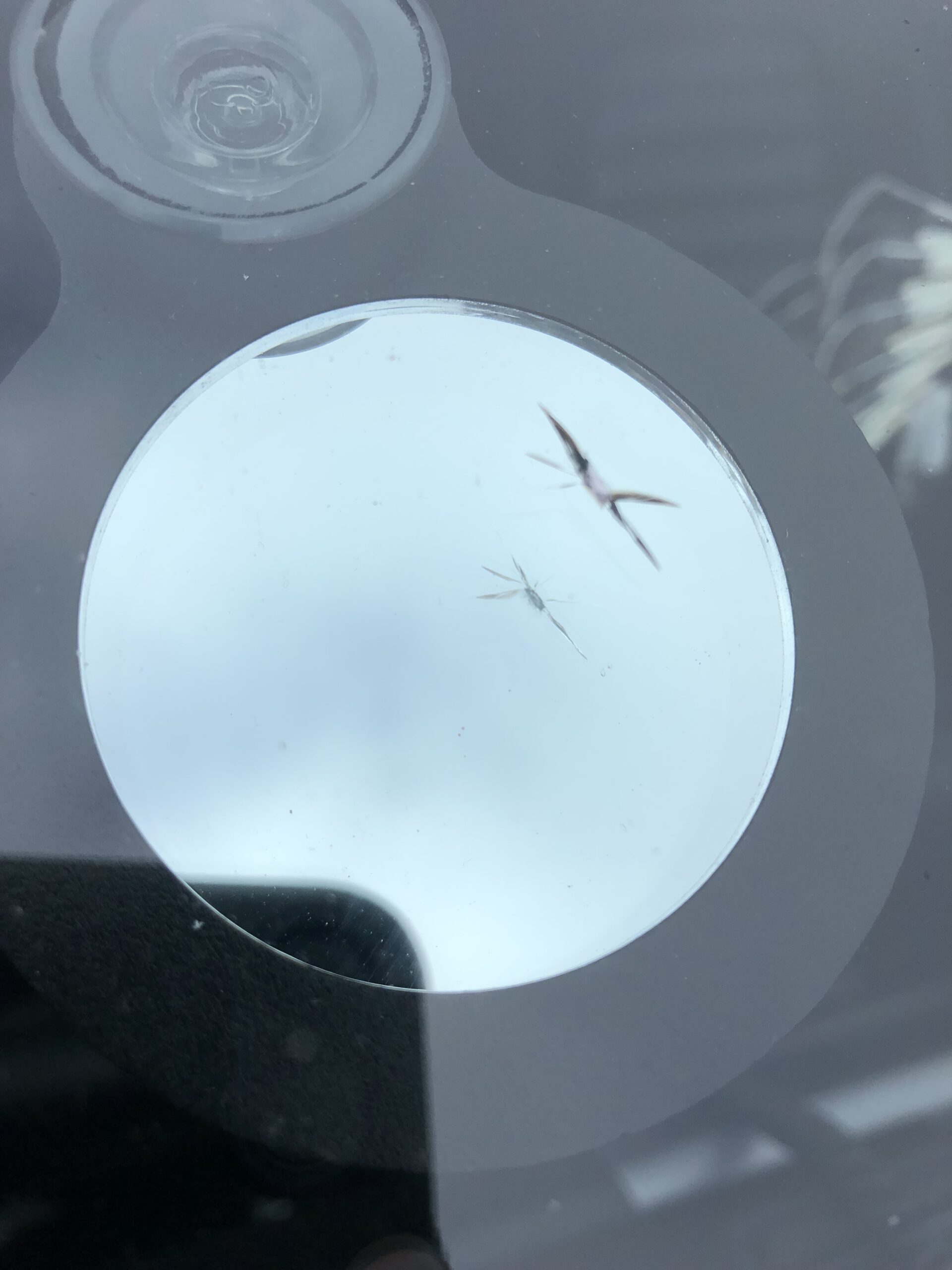

Once getting to work, he noticed a perfect star break rock chip on the passenger side of his windshield. He found my company online and booked an appointment right away. Smart guy!

I grabbed my tool box and started my windshield repair process. I flexed the legs of the chip carefully, as to not spread them out any further. I could tell that all the legs were moving quite a bit. The chip looked very fresh so the resin should fill in perfectly.

After cleaning out the crushed glass with my Dremel drill, I placed my windshield repair bridge over top of the break. I dropped a few drops of resin into the injector and placed the plunger into a pressure cycle.

The resin slowly shot itself into the middle of the break and all the legs surrounding it. After about 4 minutes, I pulled the plunger up into a vacuum cycle. I could see the air slowly being sucked out of the break.

I left the bridge on a vacuum cycle for about 3 minutes before putting the plunger back into a pressure cycle. I then flexed through the injector a few times and flexed around the legs. Everything was filling in great.

I let the machine do its work for about 20 minutes. It was a little chilly outside. To keep the glass at the right temperature, I had the customer keep his vehicle running with the heat on halfway with minimal heat.

While waiting for the rock chip to fill, the customer and I chit chatted.

After the break was filled in, I grabbed my pit resin and placed a plastic tab over top of the impact point. I placed my UV lamp over the break and let the resins cure for about 2 minutes. Next, I shaved off the excess resin with my razor blade and polished up the pit with some polish.

I cleaned up the rest of the windshield. The customer seemed pleased with the finished look and was happy that he didn’t need to worry about the chip spreading out anymore. I gave him a business card and a couple ‘fix me’ stickers.

I packed up my stuff, we exchanged goodbyes and I made my way to my next appointment. All in a days work! 😉

If you live in Edmonton and are in need of a windshield chip repair for your vehicle, please do not hesitate to contact my mobile windshield repair company.

If you missed yesterday’s blog post, you can catch up here.

All the best!

– Zach Rodgers

Owner @ Dynamo Windshield Repair