February 27, 2022

It’s Sunday Fun-day! It was a busy day today but it was still a fun day.

My day started off down in the south end of Edmonton. Then I was downtown. Then down in the southwest for a few appointments. And I finished my day off with a couple of appointments on the north side of Edmonton.

My first customer today was travelling from the Calgary area up to Edmonton to visit with some friends and family. Unfortunately, she got smacked by a big rock on the Queen Elizabeth 2 highway on her way up.

Luckily, she found my company online and was able to book an appointment for the very next day. I told her it’s smart to repair this windshield chip as soon as possible.

I grabbed my tool box and got to work.

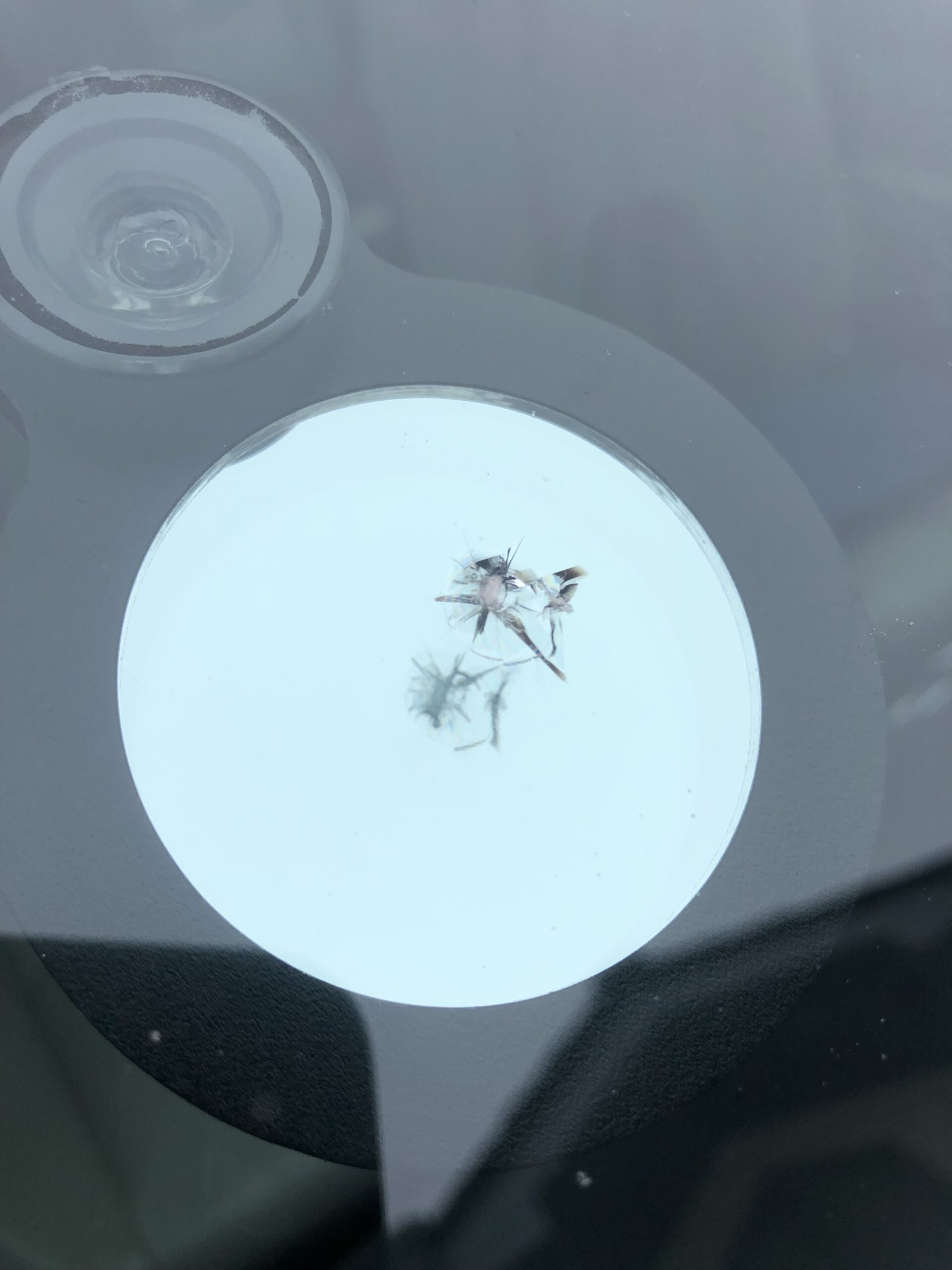

It was a decent sized combination chip with one smaller impact point below the initial impact point. This chip had quite a few radials spreading out from the middle. It’s not the worst I’ve ever seen but it definitely wasn’t the prettiest either. 😉

I grabbed my flexing tool and started to flex the glass in and around the chip. A few of the legs had some play to them. The bulls eye inside the combination chip was moving quite a bit as well. Always a good sign and it helps that this rock chip was fairly fresh.

After my flexing of the chip, I drilled into the impact point to open up the glass. Next, I grabbed my windshield repair bridge and placed it over top of the chip. I dropped a few drops of resin into the injector. I placed the plunger into a pressure cycle. I could immediately see the resin filling into the chip and the radials. Excellent!

After about 3 minutes of a pressure cycle, I flipped the injector into a vacuum cycle. I let the bridge suck out as much air as possible for about another 3-4 minutes. Next, I placed the injector back into a pressure cycle.

I chatted with the customer while inspecting the rest of the windshield. From what I could tell, she didn’t have any other rock chips. We chatted about the weather and her reason for visiting Edmonton. It was a little chilly this morning so I was careful to watch the temperature of the windshield while chitchatting.

After about 15 minutes in a pressure cycle, I could see that the chip was almost completely filled. I made sure to flex inside the injector to ensure all the air has been removed and that the resin has flowed in properly. Next, another vacuum cycle for about 2-4 minutes. Back into a pressure cycle for a couple more minutes before removing the bridge and adding some pit resin.

I placed the UV light over top and let the light do it’s job for about 2 minutes. After the curing was complete, I grabbed my razor blade and started shaving off the excess resin.

For how nasty of a rock chip this was, it cleared up fairly well. I reminded the customer about the scar leftover after a windshield chip repair. She said she was more worried about it spreading out on her way back home. I reassured her that she will be good to go, now that it has been repaired.

I polished the impact point with some pit polish and then I cleaned up the rest of the windshield area that I was working on. I gave the customer one of my business cards and a couple of “fix me” stickers for her trip back to Calgary.

We exchanged goodbyes and I wished her safe travels back home. I got in my car and made my way to my next appointment. Still got another 5 more to go. Ouuwee. Let’s get it!

If you live in Edmonton, Alberta and are in need of a windshield chip repair for your vehicle, do not hesitate to contact my mobile windshield chip repair company.

If you missed yesterday’s blog post, you can catch up here.

All the best!

– Zach Rodgers

Owner @ Dynamo Windshield Repair