Returning customers

Happy Thursday! It snowed pretty much all day today. Not the busiest of days but there were still some rock chips to be repaired in the great city of Edmonton.

It’s always a pleasure when customers who have used my mobile windshield repair service before, book an appointment with me again.

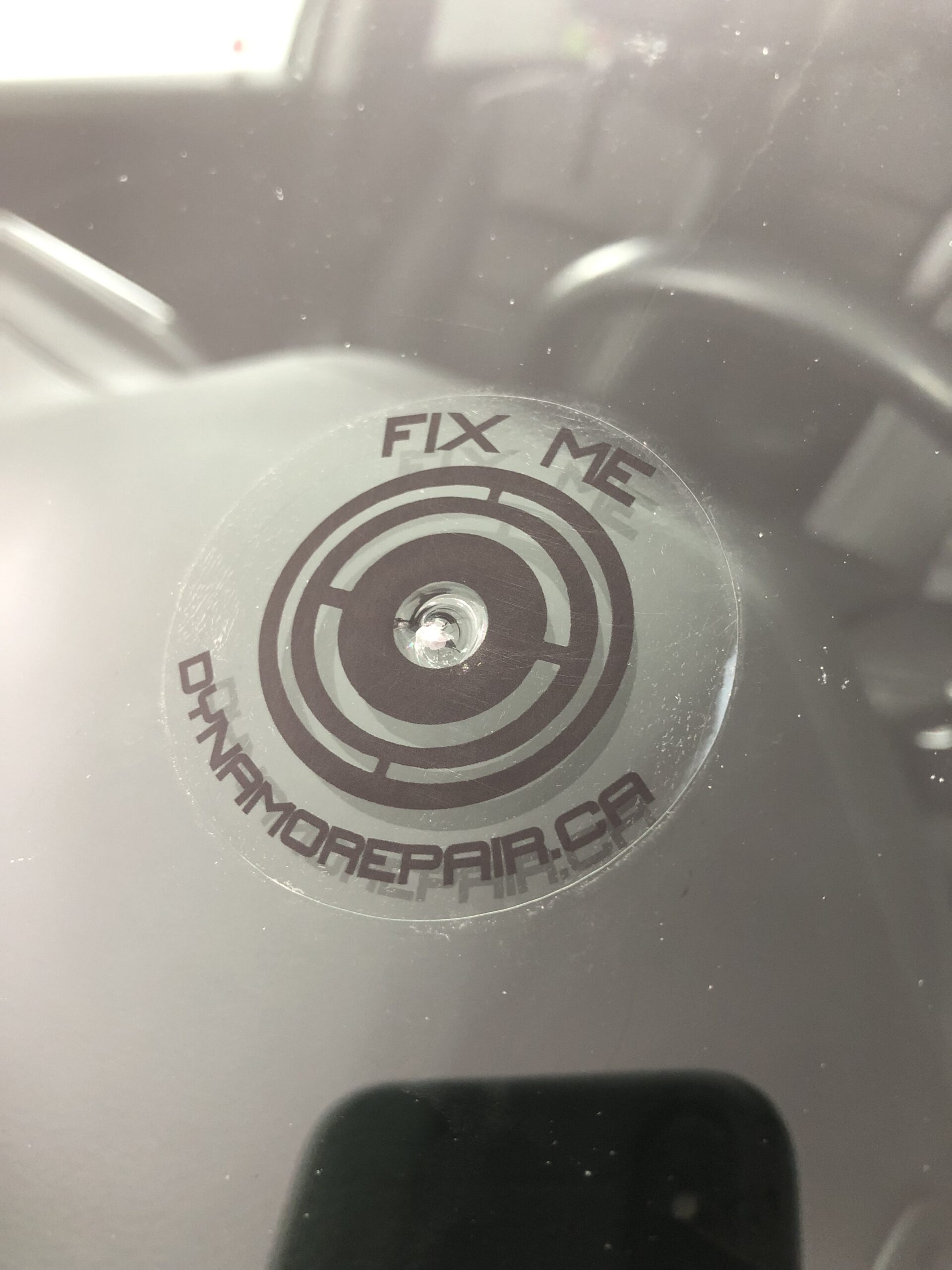

The best part is seeing my ‘fix me’ stickers on their windshield. They place these stickers over top of the new rock chip to keep it clean and dry until I can repair it.

That was the case today. A returning customer had gotten a small rock chip just a few weeks after his last appointment back in January. He told me the first thing he did was put the sticker over top of the chip and booked an appointment online. Excellent!

The rock chip was a small bulls eye with a bat wing crack in the middle. Nothing too difficult but definitely in need of a repair!

I started with my usual windshield repair process of flexing the chip and cleaning out the crushed glass with my drill bit.

After some light flexing, I placed the windshield repair bridge over top of the break. I dropped a few drops of resin into the injector and put the plunger into a pressure cycle.

The resin immediately shot into the break. I left the injector on a pressure cycle for about 3 minutes.

Next, I pulled the injector into a vacuum cycle. The air trapped inside the break was slowly being sucked out. I left the injector on a vacuum cycle for about 3-4 minutes.

I then put the injector back into a pressure cycle. I flexed through the injector a few times while leaving the injector on a pressure cycle for about another 15-20 minutes.

The customer was busy working from home, so I checked his windshield for other rock chips and caught up on some emails while waiting.

After I could tell that the chip was full of resin, I pulled the windshield repair bridge off and applied the pit resin with the plastic tab.

I turned on the Ultra Violet light and placed it over top of the rock chip. I let the lamp cure the resins for about 2-3 minutes.

Next, I cleaned off the excess resin with my razor blade and polished off the pit with my wine cork and some pit polish.

I cleaned up the windshield and let the customer know I was all done.

The customer was happy with the repair and then we chatted for a little bit before exchanging goodbyes.

I got into my car and made my way to my next appointment. After cleaning off all the snow on my car, of course. 😉

If you live in Edmonton and are in need of a windshield chip repair for your vehicle, please do not hesitate to contact my mobile windshield repair company.

If you missed yesterday’s blog post, you can catch up here.

All the best!

– Zach Rodgers

Owner @ Dynamo Windshield Repair